Why Systems Engineering Is Essential in Industrial Automation

A methodical approach for more efficient and reliable automation systems

The development of automation systems is undoubtedly complex and fraught with challenges that can derail even the most promising projects. Ambiguous requirements, misalignment between disciplines, and a trial-and-error approach commonly lead to costly delays and unnecessary expenditures. However, by proactively embracing systems engineering, organizations can establish a structured and methodical strategy. This not only enhances the efficiency of automation projects but also ensures their reliability and long-term success.

Investing in systems engineering isn't merely a wise decision; it's the essential catalyst for unlocking the full potential of automation and thriving in today’s competitive landscape.

Here’s what this post will reveal to you:

Why many automation projects fail – and how you can easily navigate around these pitfalls with systematic planning.

How Systems Engineering transforms the development process by establishing precise requirements, crafting a robust architecture, and fostering tight integration between mechanics, electronics, and software.

Proven methods for successfully developing automation systems, from requirements management to validation, encompass every stage.

The power of simulations and digital twins in identifying errors early helps you evade costly adjustments.

The enduring significance of the V-model in creating a structured and comprehensible development process.

Why do automation projects often falter despite promising outlooks?

Unfortunately, many automation initiatives spiral out of control due to critical missteps. Issues like time delays, budget overruns, and unforeseen technical challenges are not merely inconveniences; they can derail entire projects. Let’s delve into the three principal culprits: unclear requirements; insufficient coordination among mechanics, electronics, and software; and an all-too-common trial-and-error development methodology.

Too frequently, projects start with vague, ambiguous requirements that only crystallize during the implementation phase. This results in misunderstandings, costly last-minute adjustments, and elevated post-processing expenses. Over 60% of errors emerge during the conceptual phase, only to be identified later when rectification is complicated and expensive.

Additionally, the disconnect between development disciplines presents a major obstacle. When mechanics, electronics, and software are worked on separately, over 50% of integration problems emerge.

Furthermore, many companies fall back on a reactive trial-and-error approach, launching development without a coherent strategy and resolving problems only as they arise. This lack of foresight, compounded by the absence of predictive architecture and early testing, invariably breeds endless rework and escalating costs. In stark contrast, companies that embrace structured development processes can reduce their error costs, as they catch problems early in the process.

These examples reinforce the notion that the failure of many automation projects is not a byproduct of technology but a direct result of inadequate planning and coordination. The key to success lies in adopting a methodical development strategy emphasizing clear requirements, seamless discipline integration, and robust risk management—all cornerstones of Systems Engineering. The following section will illuminate how these principles can transform your automation projects into success stories.

Systems Engineering as the Catalyst for Successful Automation Solutions

In an era characterized by technological advancements, automation systems transcend the status of mere complex machines; they serve as the essential foundation for efficiency and innovation. These systems intricately integrate mechanics, electronics, and software to facilitate seamless functionality. Nevertheless, in the absence of a robust and structured methodology, unforeseen challenges may arise, leading to significant delays and financial burdens. This is where systems engineering emerges as a transformative force: it offers an interdisciplinary framework that conceptualizes the system in its entirety, establishes precise requirements, and ensures a systematic development process from initiation to completion.

Envision the significance of establishing clearly defined requirements from the outset. Systems engineering guarantees that these essential components are not merely modified throughout the project timeline; rather, they are systematically outlined, documented, and continually reassessed during the preliminary phases. This approach mitigates misunderstandings and considerably reduces the likelihood of incurring costly modifications during subsequent stages of development.

The structured system architecture represents another critical advantage. Envision all components, ranging from control software to sensors, functioning in complete harmony. This synchronization not only reduces potential errors but also improves the system's scalability, facilitating future growth without significant modifications.

Furthermore, systems engineering instills confidence through comprehensive end-to-end validation and verification processes. Each phase of development is meticulously examined, allowing for the early identification of deviations, which results in automation solutions that are not only dependable but also exceptional in quality. This proactive strategy minimizes iteration cycles, thereby conserving time and resources while enhancing overall system integrity.

By adopting systems engineering, one positions automation projects for exceptional success. It is not merely an option; it is a strategic imperative for anyone seeking to maintain a competitive advantage in the landscape of automation. Enhance your automation solutions today through the application of systems engineering principles!

Core Methodologies of Systems Engineering in Automation

To effectively address the complex challenges inherent in the development of automation systems, a systematic and structured approach is paramount. Systems Engineering offers a comprehensive array of validated methodologies, ranging from meticulous requirements definition to efficient implementation. By adopting these strategies, one can substantially mitigate the risk of significant errors and enhance the probability of success in automation projects

Requirements Management: Establishing a Solid Foundation

A significant challenge in automation projects lies in unclear or frequently changing requirements. To overcome this hurdle, Systems Engineering emphasizes the necessity of structured requirements management—systematically capturing, documenting, and overseeing all requirements. By using proven methods and tools, we can ensure that requirements are not only clearly defined from the start but also remain comprehensible throughout the project’s lifecycle.

A thorough stakeholder analysis is essential to kick off this process. It is crucial to engage all relevant stakeholders—from end users to developers to production managers—at an early stage. Techniques such as interviews, workshops, and use case analyses are employed to gather user requirements effectively and pinpoint potential conflicting objectives.

Clarity in documentation is vital to eliminating ambiguity. Creating System Requirement Specifications (SRS) according to the IEEE 29148 standard provides a structured approach to listing all functional and non-functional requirements, ensuring that every detail is meticulously captured.

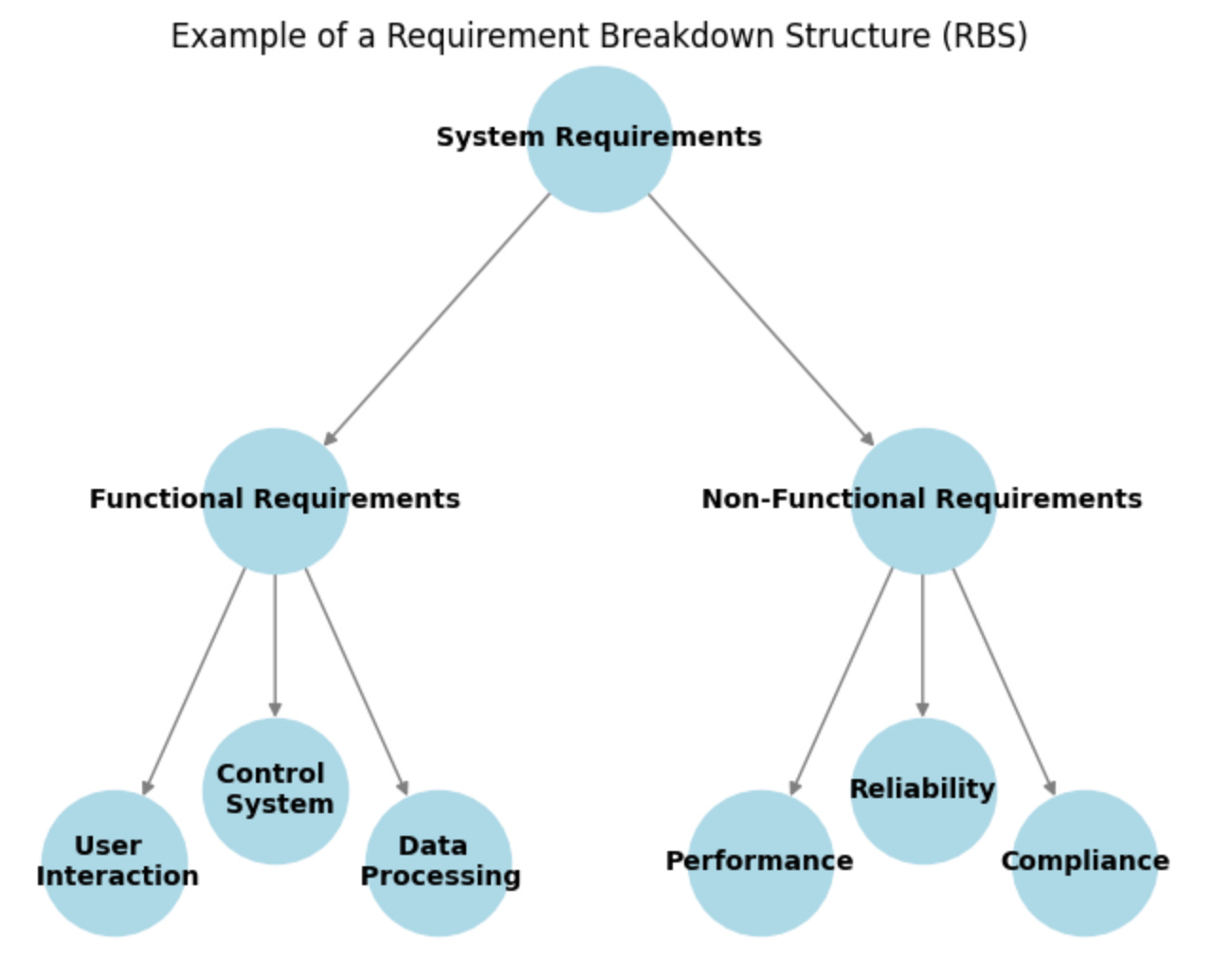

Furthermore, the preservation of traceability is of utmost importance throughout the developmental process. Implementing a traceability matrix establishes direct connections between requirements and their respective design, testing, and validation processes, thereby ensuring transparency at each phase. In addition, a Requirement Breakdown Structure (RBS) provides a hierarchical organization of requirements, which significantly aids in the effective management of complex systems. In instances where modifications occur during a project, a Change Control Process (CCP) guarantees a systematic evaluation of the implications associated with these changes.

Given that requirements can often be unclear or incomplete, early review is not just beneficial—it's crucial. The SMART criteria serve as a powerful tool for formulating requirements distinctly and verifiably. Moreover, methods such as simulations, prototyping, and Failure Mode and Effects Analysis (FMEA) enable early validation, minimizing risks and preventing costly errors later on.

Detect Errors Early for Greater Efficiency

Utilizing the capabilities of simulations and digital twins enables proactive identification of potential sources of error before they escalate into costly issues. This aspect is particularly critical for automated systems, wherein material flow simulations and robot simulations prove to be essential tools for success.

In today's interconnected production plants, every process interacts with the others, creating a complex web that influences overall performance. With material flow simulations, we can pinpoint bottlenecks, eliminate inefficient transfers, and anticipate breakpoints—long before real machines are put into operation. By optimizing buffer sizes, production speeds, and machine availability through these simulations, we can significantly enhance the efficiency of the entire system.

Moreover, robot simulations provide a unique opportunity to test motion sequences and code without the constraints of real hardware. This allows for early detection of accessibility issues, potential collisions, and cycle time violations. Consequently, programming can be optimized, and the physical commissioning process can be dramatically accelerated, leading to substantial cost savings and a quicker start-up time.

System Architecture and Design: The Crucial Framework for Automated Success

In the realm of automation, seamless interaction among components is not merely desirable; it is imperative. From mechanical elements to advanced control systems and software, each component must operate in perfect harmony. A meticulously designed system architecture guarantees that these diverse elements are not only coordinated but also optimized for optimal performance.

It establishes a foundation for modular development, permitting alterations in one domain without eliciting unintended complications in other areas. This methodology not only improves system coherence but also significantly augments scalability.

In order to establish a resilient and effective system architecture, it is essential to leverage a variety of model-based methodologies. By employing both functional and physical architectural modeling, comprehensive examination of the system's structure can be conducted. This dual perspective facilitates the posing of critical inquiries: What objectives should the system accomplish? How is the system organized? Methodologies such as the Functional Flow Block Diagram (FFBD) and the SysML Block Definition Diagram (BDD) serve as invaluable tools that illuminate the functional relationships and dependencies among the components of the system, thus enabling meticulous planning and minimizing unforeseen interactions between mechanical, electrical, and software elements.

Furthermore, the significance of modularization and interface management is paramount. By employing Modular Function Deployment (MFD), it is possible to decompose complex systems into distinctly defined functional modules, thus facilitating exceptional flexibility and scalability. The Design Structure Matrix (DSM) additionally assists in the analysis and minimization of dependencies among these modules, thereby proficiently mitigating potential integration challenges in the future. Moreover, Interface Control Documents (ICD) serve as a framework for delineating clear interfaces between modules, which aids in the early identification of incompatibilities within the design process.

Risk Management: Proactively Identify Problems Before They Arise

In the domain of automation projects, substantial investments are allocated. Consequently, risk management is not merely an alternative; it is an essential component in systems engineering. By employing structured methodologies such as Failure Mode and Effects Analysis (FMEA), we can proactively identify and assess potential risks, ensuring readiness before the emergence of issues.

FMEA is an established and systematic methodology that identifies the underlying causes of failures and their subsequent effects on the overall system. By integrating preventive measures during the planning phase, organizations can significantly minimize unplanned downtime, mitigate integration challenges, and reduce unnecessary rework costs. A detailed examination of the operational mechanics of FMEA follows:

Define System Boundaries: First, we establish clear boundaries for the system or subsystem to be analyzed—whether it’s a robotic cell, a PLC control system, or an entire production line.

Identify Possible Errors: We then identify potential failure points within each system component or process. This comprehensive analysis examines how a component might fail, the underlying causes, and the impacts on the overall system.

Risk Assessment using RPZ (Risk Priority Number): Each identified issue is evaluated through three critical criteria:

Probability of Occurrence (O): How likely is this error to occur?

Significance (B): What is the impact of this error on the system or production process?

Detectability (E): How effectively can the error be identified before it leads to significant problems?

The Risk Priority Number (RPZ) is calculated by multiplying these values (RPZ = O × B × E). A higher RPZ signals a more critical error requiring immediate action.

Define Measures to Minimize Risk: For high-risk areas with significant RPZ, targeted preventive measures must be implemented. Solutions may range from technical strategies—like redundant systems and enhanced sensor technology—to procedural improvements such as regular maintenance and refined testing procedures.

Review Effectiveness of Measures: After implementing measures, we must revisit the FMEA process to assess improvements in risk scores and determine if additional actions are necessary.

Validation and Verification: Ensuring the right System Performance

Regardless of the meticulousness of the planning, all endeavors become inconsequential if the final product does not fulfill fundamental requirements. This underscores the notion that validation and verification are not merely important; they are essential pillars of the entire development process. While verification ensures that the system complies with specified requirements, validation ascertains that it functions effectively in real-world contexts.

To guarantee the attainment of unparalleled quality control and to mitigate the risk of costly reworks, we utilize a comprehensive range of advanced methodologies and tools that have demonstrated their efficacy over time. The verification process commences with a stringent requirements-based review, employing a traceability matrix to ensure that each requirement is meticulously addressed through suitable testing protocols. In conjunction with formal reviews and inspections, we systematically examine specifications, design documents, and code, thereby detecting deviations at an early stage, which conserves both time and resources. Additionally, digital models substantially enhance this process; through the application of powerful simulations, we are able to rigorously evaluate our systems within a virtual environment prior to the development of physical prototypes.

Module and component tests are performed to assess individual software or hardware elements in isolation, thereby validating their robustness prior to their integration into the comprehensive system. This meticulous attention to detail instills confidence in our results.

Validation advances our quality assurance efforts substantially, guaranteeing that the system not only fulfills the specified requirements but also operates seamlessly in real-world conditions. System integration tests meticulously verify the interactions among all components and interfaces, thereby identifying potential friction points. During the initial phases, we leverage the capabilities of prototyping and pilot plants, which facilitate the observation of system behavior under realistic circumstances prior to the commencement of mass production.

Field tests and acceptance tests are essential for obtaining final approval. These evaluations utilize methods, including the Factory Acceptance Test (FAT) and the Site Acceptance Test (SAT), to validate and authorize the system directly within the production environment.

Building on this validation and verification approach, it becomes clear that a structured development framework is essential to seamlessly integrate these quality assurance processes into the entire lifecycle of an automation system.

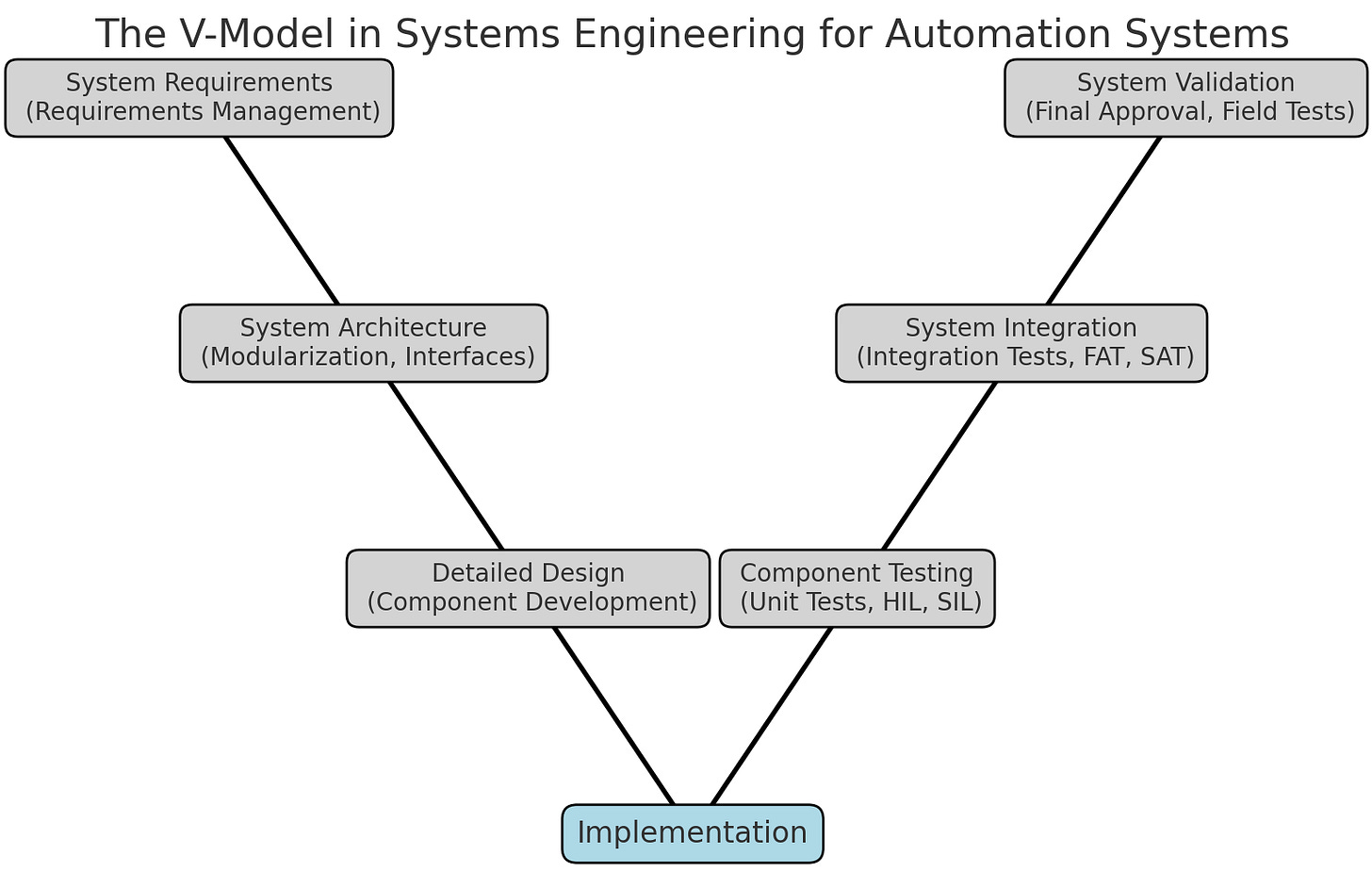

The V-Model: The Ultimate Foundation of Systems Engineering

In systems engineering, the V-model is an important process model that clearly outlines the entire development path of systems. It uses a step-by-step but flexible approach, making sure that each phase builds on the previous one and connects strongly to key verification and validation steps.

Even in a time when agile and model-based methods are popular, the V-model still plays a crucial role. It provides a clear way to handle the complexities of technical systems, especially in safety-critical and highly automated environments where accuracy and dependability are crucial.

At the heart of the V-model are two critical branches: the left side, encompassing the specification and design phase, and the right side, representing the integration and testing phase. On the left, we meticulously gather requirements, define architecture, and decompose the system into its subsystems. This is where effective requirements management takes center stage—through stakeholder analyses, traceability matrices, and comprehensive specification documents, we ensure every requirement is captured and organized with utmost precision.

Moving to the right branch of the V-model, we witness the crucial integration and testing phase—a systematic assembly process where each step is meticulously verified against its specifications. Every specification phase on the left has a corresponding verification test on the right, meticulously confirming that the system adheres to the specified requirements.

Validation tests further confirm that the system operates as intended in real-world conditions. We employ robust methodologies such as simulations, hardware/software-in-the-loop (HIL/SIL) testing, factory acceptance tests (FAT), and site acceptance tests (SAT) to secure results that inspire confidence and satisfaction.

The V-model's enduring relevance lies in its ability to provide a solid, intuitive framework for managing complex development processes. While agile methods may prioritize iterative explorations of specific sub-aspects, the V-model strategically guarantees that all requirements, interdependencies, and security considerations are systematically woven into the project's fabric from its inception.

Achieve Success in Your Automation Projects through Systems Engineering

Why do so many automation projects fail? The answer lies in factors like unclear requirements, poor coordination among mechanics, electronics, and software, and a prevalent trial-and-error methodology. These pitfalls not only lead to frustrating delays but also incur substantial remedial costs that can drain your resources.

Consider systems engineering as the cornerstone of a systematic development methodology that guarantees organized planning, mitigates risks, and facilitates the seamless integration of all components. By adopting Systems Engineering principles, one can comprehensively understand the project, utilizing precise requirements analyses, structured architectural designs, and ongoing verification and validation processes to establish a robust foundation for automation initiatives.

The V-model is a robust framework for developing automation systems. Its clear structure interlocks specification, design, integration, and testing. Even in modern, agile methodologies, the V-model remains indispensable in automation technology. Its systematic approach, emphasizing validation and verification, ensures that your projects meet and exceed expectations.